Corso Tubista Industriale

La Scuola di Metalmeccanica ITAFORMA svolge il corso per Tubista Industriale.

Obiettivo del corso è formare Tubisti pronti per le aziende metalmeccaniche

di costruzione e montaggi di Tubazioni - Piping.

Scopri come lavoriamo

Guarda il video della formazione in una delle nostre sedi in Italia.

Corso Tubista Industriale

Col nostro Corso per Tubista Industriale PipeFitter diventi un vero Tubista

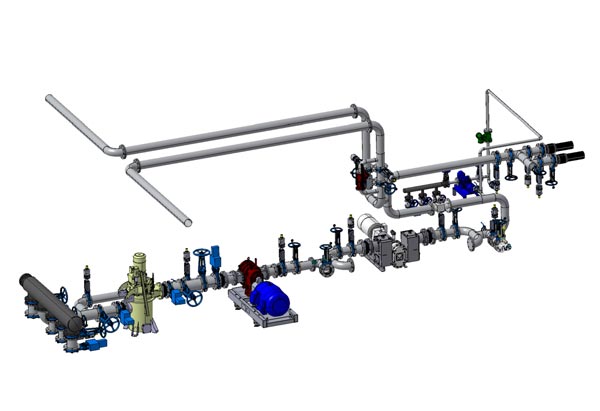

Sarai capace di saper leggere il disegno tecnico e gli sketch, orientarti nella pianta del progetto, svolgere calcoli di montaggio tubi, scegliere i pezzi per la costruzione dell’impianto, assemblare a banco e montare in impianto le linee di tubazioni con tubi, flange, curve, raccordi, valvole, ecc.

Obiettivi del Corso per Tubista Industriale

Il Corso per Tubista ha sia una parte teorica, ma soprattutto è un corso molto pratico.

Ha una durata di 140 ore e si svolge in 1 mese intenso in officina metalmeccanica. Sarai seguito da istruttori e ispettori che sono veri tubisti con pluriennale esperienza. A fine corso ti rilasciamo Certificato – Attestato di Tubista Industriale.

Programma del corso per Tubista:

Lettura del disegno Tecnico Industriale

Esercitazioni sul Disegno Tecnico Industriale

Distinzione dei vari procedimenti di saldatura e lettura delle WPS

Distinzione dei vari materiali di Raccorderia (tubi, flange, valvole, raccordi, ecc.)

Utilizzo delle attrezzature e degli utensili da lavoro del tubista per la costruzione e il montaggio

Esercitazioni pratiche di laboratorio: rilievi, misurazioni, taglio tubi manuale e con sega a nastro, tracciatura, esecuzione smussi

Utilizzo della saldatrice e mettere i punti di saldatura tra tubi

Assemblaggio e montaggio delle tubazioni

Compiti del Tubista Industriale PipeFitter

Un Tubista Industriale PipeFitter specializzato, si occupa a 360°

di tutte le attività relative alla costruzione, montaggio e riparazione di tubazioni.

Studia e pianifica il progetto da realizzare, prende le misure sul campo, svolge rilievi in opera, sceglie e raccoglie il materiale necessari seguendo le specifiche del progetto, traccia i tubi che deve lavorare, esegue gli smussi sul tubo, assembla tubi con altri tubi, flange, raccordi, valvole in modo da costruire delle linee di tubazioni e monta in impianto le tubazioni prefabbricate.

Trovare lavoro come

Tubista Industriale

Il Tubista Industriale è uno dei mestieri più ricercati dal mondo del lavoro

Sono pochi i Tubisti industriali specializzati e trovano lavoro facilmente e rapidamente, perché il tubista è molto utilizzato in diversi campi di applicazione della metalmeccanica.

Il tubista o Pipefitter costruisce e monta tubazioni per raffinerie di petrolio, impianti energetici, alimentari, farmaceutici, costruisce tubazioni per acquedotti, gasdotti, oleodotti, lavora per aziende di servizi pubblici e privati, costruisce impianti per ospedali, navi, edilizia, impianti di riscaldamento, ventilazione, ecc.

È un lavoro molto ben retribuito, lo stipendio varia in base se sei un tubista di costruzione in officina, o un tubista di montaggio in cantiere-impianto.

Il tubista normalmente lavora in coppia con il saldatore, altra figura professionale molto ricercata dal mondo del lavoro, il tubista accoppia i tubi o i pezzi di una linea di tubazione e il saldatore li salda.

C’è differenza tra un tubista industriale che costruisce, assembla e monta tubazioni industriali e per impianti e un idraulico civile che invece lavora solo nel campo dell’edilizia civile.

Il nostro Corso per Tubista Industriale è il più completo e pratico d’Italia.

Stipendio Tubista Industriale

Il Tubista è una mansione ben retribuita, soprattutto perchè difficile da trovare per le aziende.

Il tubista percepisce lo stipendio in base alle abilità che possiede, all’esperienza maturata, alla durata dei contratti lavorativi, se è un Tubista Junior o con esperienza, se è tubista di prefabricazione d’officina o di montaggi in cantieri.

In generale il tubista in Italia in media percepisce tra:

– 1650€ netti ( per un Tubista Junior )

– fino a 3000€ netti ( per un Tubista completo con esperienza ).

Programma Dettagliato

Corso Tubista Industriale - PipeFitter

- Consapevolezza della mansione;

- Lettura Disegno;

- Riconoscimento simboli;

- Riconoscimento pezzi e spessori;

- Verifica spessori;

- Unità di misura usate;

- Strumenti di misura;

- Cenni variazione dimensionali in funzione della temperatura;

- Differenze nella lavorazione dei materiali, ferrosi, inossidabili e non ferrosi. Tipi di approccio non ferrosi;

- Contaminazione dei materiali;

- Taglio e tracciabilità del Piping;

- Tipi di stampigliature (marcatori indelebili o punzoni antistress);

- Identificazione della qualità dei materiali previsti da disegno;

- Numero di colata/lotto dei materiali;

- Preparazione per protezioni a rovescio con l’uso di gas inerti;

- Tracciatura al banco di pezzi a misura su sagoma, riporto su tubo ed adattamento tracciatura e realizzazione di falso tubo;

- Tracciatura e realizzazione di piastre di rinforzo tracciatura di realizzazione collari;

- Montaggio dei supporti; Vari tipi di supporti e loro scopo;

- Foratura piastre di rinforzo ed equivalenti;

- Tolleranze di accoppiamento esempi secondo ASME B31.3

- Uso del cannello ossiacetilenico, principi di funzionamento schema di impianto, riduttore di pressione, valvola idraulica, valvola a secco, valvola di sicurezza;

- Preparazione al taglio previo tracciatura e bulinatura, esercitazione al taglio su tubi di vario spessore diametro; Cenni e dimostrazioni di saldatura autogena;

- Sega a nastro e tipo di lama;

- Fresatubi, smussatrici e cianfrinatrici cenni;

- Scelta del tipo di processo di taglio in funzione del materiale base;

- Puntatura secondo WPS ed applicazione del gas di protezione e/o preriscando quando previsti;

- Elementi di base per l’utilizzo della saldatrice.

Uso del cannello ossiacetilenico, principi di funzionamento schema di impianto, riduttore di pressione, valvola idraulica, valvola a secco, valvola di sicurezza;

Preparazione al taglio previo tracciatura e bulinatura, esercitazione al taglio su tubi di vario spessore diametro; Cenni e dimostrazioni di saldatura autogena; Sega a nastro e tipo di lama; Fresatubi, smussatrici e cianfrinatrici cenni; Scelta del tipo di processo di taglio in funzione del materiale base; Puntatura secondo WPS ed applicazione del gas di protezione e/o preriscando quando previsti; Elementi di base per l’utilizzo della saldatrice.

- Interpretazione dello sketch nello spazio;

- Comprensione degli spostamenti e delle quote, utilizzo delle viste, procedure di montaggio delle flange con rispetto delle forature;

- Montaggio delle curve realizzazione di spostamenti,

- Realizzazione di branchi;

- Posizionamento delle saldature longitudinali;

- Distanza minima tra giunti saldati

- Tolleranze dimensionali finali spool secondo PFI ES-3 o EN13480-4;

- Uso di trapano a base magnetica per realizzo di foratura su tubi;

- Preparazione dei lembi in raccordi a T di tubazione di diametro differenti;

- Preparazione dei lembi in raccordi a T di tubazione di diametro uguali;

- Assemblaggio dell’intero sketch con marcatura punzonatura low stress o cartellinatura per riconoscimento.

- Simboli di accoppiamento per saldatura in opera.

- Verifica del manufatto eseguito controllo del disegno di insieme verifica del rispetto delle schedule dei vari accessori controllo degli orientamenti riconoscimento dei punzoni, controllo dimensionale;

- Identificazione dello spool;

- Utilizzo dei mezzi di sollevamento interni ed esterni, conoscenza dei simboli manuali per le movimentazioni;

- Utilizzo di Tirfort, ranette e martinetti, esercitazione pratica in opera.

Materiali, strumenti e attrezzature che utilizzerai

durante il Corso di Tubista Industriale

Durante il nostro Corso di Tubista Industriale, imparerai a conoscere i diversi materiali e pezzi necessari per costruire le linee di tubazioni, infatti utilizzerai e monterai tubi, flange, raccordi, valvole, guarnizioni, ecc. Utilizzerai strumenti di misura, attrezzature, e utensili, come: livella a bolla, calibri, metri, compassi, mole-smerigliatrici, cavalletti per tubi, saldatrice, sega a nastro, accoppiatori, tagliatubi, ecc.

Svolgiamo Corso Tubisti per Privati e Aziende

Programmi studiati su misura ed in base alle necessità.

Tutti i nostri Corsi di Metalmeccanica

Scegli il corso più adatto alle tue esigenze di lavoro

Corso Saldatore Elettrodo

Base

Corso MMA SMAW 40h pratica + 10h teoria

Corso Saldatore Elettrodo

Intermedio

Completo MMA SMAW 80h pratica + 20h teoria

+ Saldatrice in omaggio

Corso Saldatore Elettrodo

Completo

Corso MMA SMAW 120h pratica + 25h teoria

Corso Saldatore TIG

Base

Corso GTAW 40h pratica + 10h teoria

Corso Saldatore TIG

Intermedio

Completo GTAW 80h pratica + 20h teoria

+ Saldatrice in Omaggio

Corso Saldatore TIG

Completo

Completo GTAW 96h pratica + 20h teoria

+ Saldatrice in Omaggio

Corso Saldatore TIG

SUPER COMPLETO

Completo GTAW 112h pratica + 25h teoria

+ Saldatrice in Omaggio

Corso saldatore Filo continuo

Base

Corso Mig Mag 40h pratica + 10h teoria

Corso Saldatore Filo Continuo

INTERMEDIO

Corso Mig Mag 80h pratica + 20h teoria

Corso Saldatore Filo Continuo

completo

Completo Mig Mag 100h pratica + 25h teoria

Corso Saldatore Filo Continuo

SUPER COMPLETO

Corso Mig Mag 116h pratica + 25h teoria

Corso Saldatore Tig + Elettrodo

Completo

140h pratica + 30h teoria

Corso Saldatore Tig + Filo continuo Completo

180h pratica + 40h teoria

Corso Saldatore Elettrodo + Filo continuo Completo

180h pratica + 40h teoria

Corso Saldatore TIG + Elettrodo + Filo Continuo COMPLETO

240h pratica + 60h teoria

Corso Saldatore TIG + Elettrodo + Filo Continuo SUPER COMPLETO

272h pratica + 60h Corsi Teorici inclusi + Saldatrice in omaggio

Corso Tubista Industriale

140h pratica + 30h teoria

Corso Fabbro Carpentiere

140h pratica + 30h teoria

Corso Lettura disegno tecnico meccanico

Corso di 21h in presenza e online.

I nostri corsi si svolgono in modalità diurna intensiva, durante tutto l’anno,

dal lunedì al venerdì, 8 ore al giorno di pratica/saldatura.

I nostri corsi si svolgono in modalità diurna intensiva, durante tutto l’anno, dal lunedì al venerdì, 8 ore al giorno di pratica/saldatura.

Contattaci

Compila il form con i tuoi dati e verrai ricontattato in brevissimo tempo dalla nostra Scuola che ti fornirà tutte le informazioni che necessiti.