Electrode Welding Course (SMAW - MMA)

Electrode Welding Course (SMAW - MMA) - Our Welding School conducts professional electrode welding courses, issuing a Welding License according to UNI EN 9606 and UNI EN 287 Certification.

Our Welding School is recognized as one of the best in Italy, hundreds of trainees through our Electrode Welding Course have become professional welders and are working in the best engineering companies in Europe.

After the Electrode Welder Course, we have many services to help you find a job as a welder.

How long does it take to learn how to weld

during the Electrode Welding Course

(SMAW - MMA)

Our Electrode Welder Course is very hands-on, 80 intense hours of pure welding, starting from 0 and preparing you to pass the Welding License exam and the tests that companies give you before hiring you.

The Electrode Welder Course takes place 8 hours a day for 15 days.

We conduct welding courses in all Italian provinces upon reaching number of 5 enrolled, call us to see when the course nearest to you starts. In our main production workshop, the course is held every day of the year, so you can enroll whenever you want, don't worry if you are far away, we give you room and board Free of charge for the duration of the course.

What is Electrode Welding?

Coated electrode welding is a manual autogenous welding process that takes advantage of the heat generated by an arc striking between a fusible coated electrode and the workpiece. This process is one of the most commonly used in welding, mainly because of the advantage of its versatility.

What can be accomplished with Electrode Welding?

In fact, it makes it possible to make joints in any position, to weld on the shop floor or in confined and confined areas (e.g., double bottoms of ships, inside of equipment, inside parts of structures) and even, with some precautions against drafts and rain, in the Shipyard. When the generator is heavy and not easily transportable, power cables can be sufficiently long to handle.

Almost all ferrous and nonferrous metals (e.g., nickel and its alloys) are welded by this process. Insufficiently good results are obtained with aluminum and its alloys and with pure copper and some of its alloys, while low melting point metals such as zinc, lead, tin, or those requiring special protection such as titanium and its alloys cannot even be welded. The operational limitations of the process consist of limited productivity, since each worn electrode must be replaced with a new one and slag must be removed from the deposited metal after each pass.

Our Electrode Welding Course, consists largely of hands-on workshop exercises.

Itaforma Electrode Welding Course

Our Welding School, is not just a School, it is a real manufacturing engineering company, so we know what companies look for from an electrode welder, in fact we have developed an excellent welding course program.

Our ITAFORMA Welding School takes care of everything you need to get you through the course, in fact our offer includes: Welder's clothing and shoes, PPE (Safety Equipment), electrode welder, welding materials, filler materials, workbench, tool chest with everything you need (mask, brush, apron, welder's cap, tools and equipment), free lunch and dinner canteen, accident insurance, free housing for the duration of the course, Welding License , etc.

Our Welding Instructors, are great professionals, with lots of working experience in welding, you will be followed throughout the course by certified Welding Instructor and Inspector.

What are the job opportunities as Electrode Welder?

The Electrode Welder is one of the most in-demand professional figures in the job market, today hundreds of companies in Italy are constantly looking for quality, licensed welders to be included in their productions.

The Electrode welder is in demand in so many fields of engineering, especially by the many light carpentry and building construction companies, if the electrode welder can also TIG weld, it opens up to all sectors of oil refining, energy, pharmaceutical, food, etc.

Companies are looking for ready-made welders to go into production; for those starting from 0, choosing a Professional Welding Course is the easiest and fastest Way to learn welding well and take advantage of the high demand for welders to find work.

Our Welding School is distinguished not only by the quality and practicality of the course, but also by the very important free services that help our trainees in their search for a Job as an Electrode Welder.

Do you want to find a job as an Electrode Welder?

How do you find Jobs for Electrode Welder?

This is the search and selection process for metal companies:

The company posts online and offline (through job agencies or other channels) a job application for a welder

Once the company receives applications, only welders who have a Welding License or have already worked with the company are chosen

The company has an in-house welding test conducted in its shop, usually very similar to the examination for the License

Our Welding School, makes you train precisely on the possible welding tests you may come across during the examination of the Electrode Welder's License and the tests the company might subject you to before hiring you.

Find out how we work

This is what you will find if you choose ITAFORMA, one of the Best Welding Schools in Europe.

Che scuola bisogna fare per fare il Corso di Saldatura ad Elettrodo e ricevere il Patentino di Saldatura ad Elettrodo (SMAW - MMA) ?

The Electrode Welding License according to UNI EN 9606 or UNI EN 287 certification is the most important qualification a welder can have; it attests to the excellent qualities of the electrode welder. Our Welding Course is built to prepare you to pass the exam and receive the Welding License.

When is a welder's license mandatory?

The license has been mandatory since July 1, 2014 for everyone working in companies and workshops. Our Welding School guarantees you will achieve the goal Electrode Welding License even if you start from 0.

To take the Welding License, there are no recommendations, you have to be a high-quality welder and on the day of the exam in front of a Welding Inspector, you have to perform welds that will be judged visually and in the laboratory through breakage tests or x-rays.

So it is recommended that you choose a very professional Electrode Welding Course that will get you there.

What will you learn in the Electrode Welding Course?

During the Electrode Welding Course, you will learn how to weld in different positions so that you will be ready for all potential job requirements:

Electrode Welding in the Flat Position

Electrode welding in vertical upward position

Electrode Welding in the Flat Position

Electrode Welding in the Sopratesta Position

Electrode Welding in Frontal Position

Electrode welding in vertical descending position

Electrode welding on sheet metal

Electrode welding for piping on positioner

Electrode welding for pipes on bench and in place

The Coated Electrode

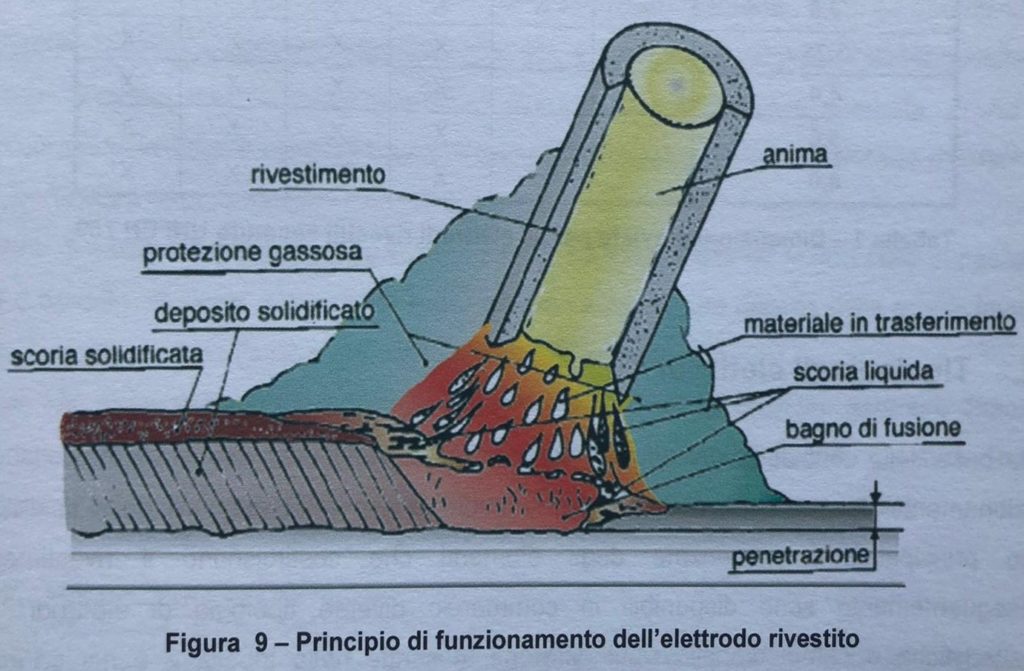

During the Electrode Welding Course, we will teach you how to choose and use the electrode according to the characteristics of the base material to be welded. The coated electrode consists of two parts namely, a metal core that acts as a filler material and a coating that provides protection.

During welding, the electrode core melts and, in the form of droplets, transfers into the weld pool; at the same time, the cladding also follows the core into the weld pool. Part of the filler material volatilizes, creating gases that protect the arc, reducing the danger of oxidation.

What is the welding electrode?

The coated electrode is the only consumable in this welding process. It consists of a metal core around which is a coating; during welding there is melting of the core, which in the form of droplets is transferred to the melting bath, as well as of a part of the coating that follows that of the core with a certain delay, so as to form a kind of cup at the end of the electrode.

Part of the coating volatilizes with gas formation that replaces air in the arc zone, reducing the danger of bath contamination. The melting part of the coating wraps around the droplets, protecting them during transfer, enters the melt bath, reacts chemically with it, and is quickly brought to the surface: after solidification, it constitutes the "slag," which must be subsequently removed.

During the Electrode Welder Course we will teach you and let you try different types of electrodes.

Types of Electrode Coating

The electrode differs in material composition, size, and coating. There are different types of coating:

Acid Coating

Cellulosic coatings

Rutile coatings

Basic coatings

What are the risks and defects of Electrode Welding?

During the Electrode Welding Course, we will teach you how to make the highest quality welds and thus avoid the following and common defects of electrode welding beads.

Basic coatings

Marginal engravings

Cracks (Hot and cold cracks)

Lack of in-plane, corner and fusion penetration

Irregular appearance

Blowouts

Lack of metal

Excessive overthickness

Porosity

Electrode Welding Machine

The electrode welding equipment consists of a generator and two clamps: one for the ground and the other for the electrode holder.

The Generator of the Electrode Welding Machine can operate on direct and alternating current and must have the necessary power to trigger the electric arc and keep it stable throughout the welding process.

All of our Metalworking Courses

Choose the course that best suits your business needs

Corso Saldatore Elettrodo

Base

Corso MMA SMAW 40h pratica + 10h teoria

Corso Saldatore Elettrodo

Intermedio

Completo MMA SMAW 80h pratica + 20h teoria

+ Saldatrice in omaggio

Corso Saldatore Elettrodo

Completo

Corso MMA SMAW 120h pratica + 25h teoria

Corso Saldatore TIG

Base

Corso GTAW 40h pratica + 10h teoria

Corso Saldatore TIG

Intermedio

Completo GTAW 80h pratica + 20h teoria

+ Saldatrice in Omaggio

Corso Saldatore TIG

Completo

Completo GTAW 96h pratica + 20h teoria

+ Saldatrice in Omaggio

Corso Saldatore TIG

SUPER COMPLETO

Completo GTAW 112h pratica + 25h teoria

+ Saldatrice in Omaggio

Corso saldatore Filo continuo

Base

Corso Mig Mag 40h pratica + 10h teoria

Corso Saldatore Filo Continuo

INTERMEDIO

Corso Mig Mag 80h pratica + 20h teoria

Corso Saldatore Filo Continuo

completo

Completo Mig Mag 100h pratica + 25h teoria

Corso Saldatore Filo Continuo

SUPER COMPLETO

Corso Mig Mag 116h pratica + 25h teoria

Corso Saldatore Tig + Elettrodo

Completo

140h practice + 30h theory

Corso Saldatore Tig + Filo continuo Completo

180h pratica + 40h teoria

Corso Saldatore Elettrodo + Filo continuo Completo

180h pratica + 40h teoria

Corso Saldatore TIG + Elettrodo + Filo Continuo COMPLETO

240h pratica + 60h teoria

Corso Saldatore TIG + Elettrodo + Filo Continuo SUPER COMPLETO

272h pratica + 60h Corsi Teorici inclusi + Saldatrice in omaggio

Industrial Tubist Course

140h practice + 30h theory

Course Blacksmith Carpenter

140h practice + 30h theory

Mechanical technical drawing reading course

Corso di 21h in presenza e online.

Our courses are held in intensive daytime mode, throughout the year,

Monday through Friday, 8 hours a day of practice/welding.

Our courses are held in intensive daytime mode, throughout the year, Monday through Friday, 8 hours a day of practice/welding.

Contact us

Fill out the form with your details and you will be contacted in a very short time by our School who will provide you with all the information you need.