Shielded Metal Arc Welding (SMAW - MMA) Course

Shielded Metal Arc Welding (SMAW – MMA) Course – Our Welding School conducts professional shielded metal arc welding courses, leading to the issuance of a Welding Qualification according to UNI EN 9606 and UNI EN 287 certifications.

Our Welding School is recognized as one of the best in Italy; hundreds of students, through our Shielded Metal Arc Welding Course, have become professional welders and now work in Europe's top metalworking companies.

After the Shielded Metal Arc Welder Course, we offer numerous services to help you find employment as a welder.

How long does it take to learn welding

during the Shielded Metal Arc Welding Course

(SMAW - MMA)

Our Shielded Metal Arc Welder Course is highly practical, featuring 80 intensive hours of hands-on welding; you start from scratch, and we prepare you to pass the Welding Qualification exam and the tests companies administer before hiring.

The Shielded Metal Arc Welder Course is conducted 8 hours a day for 15 days.

We conduct welding courses in all Italian provinces once a minimum of 5 participants is reached; call us to inquire about the nearest available course. At our main production workshop, the course runs every day of the year, so you can enroll at any time. Don't worry if you're far away; we provide free room and board for the entire duration of the course.

What is Shielded Metal Arc Welding?

Shielded metal arc welding (SMAW) is a manual autogenous welding process that utilizes the heat generated by an arc struck between a consumable coated electrode and the workpiece. This process is one of the most commonly used in welding, primarily due to its versatility.

What can be achieved with Shielded Metal Arc Welding?

It allows for the creation of joints in any position, for welding in workshops or in restricted and confined areas (e.g., ship double bottoms, inside equipment, internal structural parts), and also, with some precautions against drafts and rain, on construction sites. When the power source is heavy and not easily transportable, the power cables can be sufficiently long and manageable.

This process can weld almost all ferrous and non-ferrous metals (e.g., nickel and its alloys). Insufficiently good results are obtained with aluminum and its alloys, as well as with pure copper and some of its alloys, while low-melting-point metals like zinc, lead, tin, or those requiring special protection such as titanium and its alloys, cannot be welded at all. The operational limitations of the process include limited productivity, as each consumed electrode must be replaced with a new one, and slag must be removed from the deposited metal after each pass.

Our Shielded Metal Arc Welding Course consists largely of practical workshop exercises.

Itaforma Shielded Metal Arc Welding Course

Our Welding School is not just a school; it is a genuine productive metalworking company. Therefore, we know exactly what companies look for in a shielded metal arc welder. In fact, we have developed an excellent curriculum for the welding course.

Our Welding School ITAFORMA takes care of everything you need to complete the course; in fact, our offer includes: Welder's clothing and shoes, PPE (Personal Protective Equipment), electrode welding machine, materials to be welded, filler materials, workbench, toolbox with all necessary items (mask, brush, apron, welder's cap, tools and equipment), free canteen for lunch and dinner, accident insurance, free accommodation for the entire duration of the course, Welding Certificate, etc.

Our Welding Instructors are highly skilled professionals with extensive practical welding experience; you will be guided throughout the course by certified Welding Instructors and Inspectors.

What are the job opportunities as a Shielded Metal Arc Welder?

The Electrode Welder is one of the most in-demand professional figures in the job market; today, hundreds of companies in Italy are constantly seeking qualified and certified welders to integrate into their production processes.

The Electrode Welder is highly sought after in numerous fields within the metalworking industry, particularly by many light fabrication and construction companies. Furthermore, if an electrode welder can also perform TIG welding, opportunities expand into all sectors such as oil refining, energy, pharmaceutical, food, etc.

Companies are looking for welders who are immediately ready for production. For those starting from scratch, choosing a professional Welding Course is the simplest and fastest way to learn welding proficiently and capitalize on the high demand for welders to secure employment.

Our Welding School stands out not only for the quality and practical nature of its courses but also for the highly valuable free services that assist our students in their search for employment as an Electrode Welder.

Do you want to find a job as a Shielded Metal Arc Welder?

How to find Employment as an Electrode Welder?

This is the recruitment and selection process for metalworking companies:

The company advertises the welder vacancy online and offline (through employment agencies or other channels).

Once the company receives applications, only welders who possess a Welding Certification or have previously worked with the company are selected.

The company conducts an internal welding test in its workshop, which is usually very similar to the certification exam.

Our Welding School trains you specifically for the potential welding tests you might encounter during the Shielded Metal Arc Welder Certificate exam and the tests a company might administer before hiring you.

Discover how we work

This is what you will find if you choose ITAFORMA, one of the Best Welding Schools in Europe.

Che scuola bisogna fare per fare il Corso di Saldatura ad Elettrodo e ricevere il Patentino di Saldatura ad Elettrodo (SMAW - MMA) ?

The Electrode Welding Certification, according to UNI EN 9606 or UNI EN 287 standards, is the most crucial qualification a welder can possess, attesting to the excellent skills of an electrode welder. Our Welding Course is designed to prepare you to pass the exam and obtain the Welding Certification.

When is a welder's certificate mandatory?

The certificate has been mandatory since July 1, 2014, for all those working in companies and workshops. Our Welding School guarantees you will achieve the Shielded Metal Arc Welding Certificate, even if you start from scratch.

To obtain the Welding Certificate, there are no shortcuts; you must be a high-quality welder. On the day of the exam, in front of a Welding Inspector, you must perform welds that will be judged visually and in the laboratory through destructive or radiographic testing.

Therefore, it is advisable to choose a highly professional Shielded Metal Arc Welding Course that leads you to this result.

What will you learn during the Electrode Welding Course?

During the Electrode Welding Course, you will learn to weld in various positions to be prepared for all potential job requirements:

Electrode Welding in Flat Position

Electrode Welding in Vertical Up Position

Electrode Welding in Flat Position

Electrode Welding in Overhead Position

Electrode Welding in Horizontal Position

Electrode Welding in Vertical Down Position

Electrode Welding on Plates

Electrode Welding for Piping on Positioner

Electrode Welding for Pipes on Bench and In-Situ

The Covered Electrode

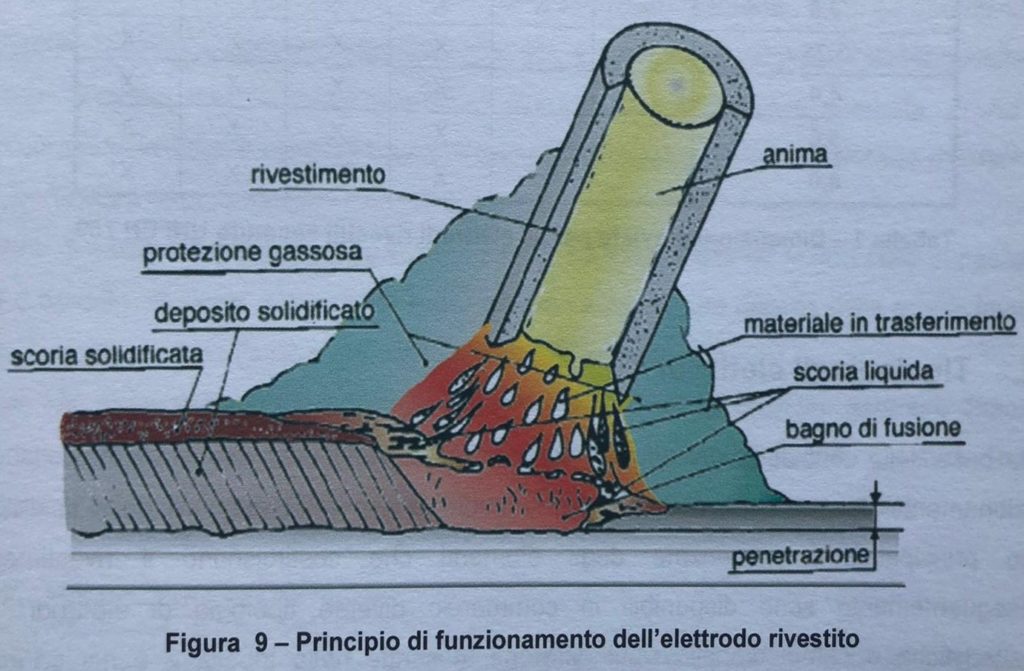

During the Electrode Welding Course, we will teach you how to select and use the electrode based on the characteristics of the base material to be welded. The coated electrode consists of two parts: a metallic core that serves as filler material and a coating that provides protection.

During welding, the electrode core melts and, in the form of droplets, transfers into the weld pool; simultaneously, the coating also follows the core into the weld pool. A portion of the filler material volatilizes, creating gases that protect the arc, thereby reducing the risk of oxidation.

What is a Welding Electrode?

The coated electrode is the only consumable in this welding process. It consists of a metallic core surrounded by a coating; during welding, the core melts and, in the form of droplets, transfers into the weld pool, along with a portion of the coating that follows the core with a slight delay, forming a cup-like shape at the electrode tip.

A portion of the coating volatilizes, forming gases that displace air in the arc zone, reducing the risk of weld pool contamination. The molten part of the coating envelops the droplets, protecting them during transfer, enters the weld pool, chemically reacts with it, and quickly rises to the surface: after solidification, it forms the “slag,” which must be subsequently removed.

During the Electrode Welder Course, we will teach you and let you try different types of electrodes.

Types of Electrode Coatings

Electrodes are distinguished by material composition, dimensions, and coating. There are several types of coatings:

Acidic Coating

Cellulosic Coatings

Rutile Coatings

Basic Coatings

What are the risks and defects of Shielded Metal Arc Welding?

During the Electrode Welding Course, we will teach you how to perform high-quality welds and thus avoid the following common defects in electrode weld beads.

Basic Coatings

Undercuts

Cracks (Hot and Cold Cracks)

Lack of Penetration (flat and fillet welds) and Lack of Fusion

Irregular Weld Profile

Porosity

Underfill

Excessive Reinforcement

Porosity

Stick Welder

Stick welding equipment consists of a power source and two clamps: one for the ground and the other for the electrode holder.

The power source of a Stick Welder can operate with both direct current and alternating current, and must have sufficient power to ignite the electric arc and maintain its stability throughout the welding process.

All our Metalworking Courses

Choose the course most suitable for your professional requirements

Corso Saldatore Elettrodo

Base

Corso MMA SMAW 40h pratica + 10h teoria

Corso Saldatore Elettrodo

Intermedio

Completo MMA SMAW 80h pratica + 20h teoria

+ Saldatrice in omaggio

Corso Saldatore Elettrodo

Completo

Corso MMA SMAW 120h pratica + 25h teoria

Corso Saldatore TIG

Base

Corso GTAW 40h pratica + 10h teoria

Corso Saldatore TIG

Intermedio

Completo GTAW 80h pratica + 20h teoria

+ Saldatrice in Omaggio

Corso Saldatore TIG

Completo

Completo GTAW 96h pratica + 20h teoria

+ Saldatrice in Omaggio

Corso Saldatore TIG

SUPER COMPLETO

Completo GTAW 112h pratica + 25h teoria

+ Saldatrice in Omaggio

Corso saldatore Filo continuo

Base

Corso Mig Mag 40h pratica + 10h teoria

Corso Saldatore Filo Continuo

INTERMEDIO

Corso Mig Mag 80h pratica + 20h teoria

Corso Saldatore Filo Continuo

completo

Completo Mig Mag 100h pratica + 25h teoria

Corso Saldatore Filo Continuo

SUPER COMPLETO

Corso Mig Mag 116h pratica + 25h teoria

Corso Saldatore Tig + Elettrodo

Completo

140h practical + 30h theory

Corso Saldatore Tig + Filo continuo Completo

180h pratica + 40h teoria

Corso Saldatore Elettrodo + Filo continuo Completo

180h pratica + 40h teoria

Corso Saldatore TIG + Elettrodo + Filo Continuo COMPLETO

240h pratica + 60h teoria

Corso Saldatore TIG + Elettrodo + Filo Continuo SUPER COMPLETO

272h pratica + 60h Corsi Teorici inclusi + Saldatrice in omaggio

Industrial Pipefitter Course

140h practical + 30h theory

Blacksmith-Metal Fabricator Course

140h practical + 30h theory

Mechanical Technical Drawing Reading Course

Corso di 21h in presenza e online.

Our courses are conducted in an intensive daytime format, year-round,

Monday to Friday, with 8 hours per day of practical training/welding.

Our courses are conducted in an intensive daytime format, year-round, Monday to Friday, with 8 hours per day of practical training/welding.

Contact Us

Fill out the form with your details, and our School will contact you shortly to provide all the information you need.