Submerged arc welding

Submerged-arc welding using the En ISO 1-121 process transforms the classic figure of the welder into a true specialized machine operator.

Submerged Arc Welding allows for a significant amount of material input per welding pass, in fact it cuts down the welding time so much. Unlike other welding procedures, no space (air) is left between the two parts to be welded-joints, it will be the penetrating power of the machine on one side and then the reverse shot on the other side that will allow the joint to be totally welded.

Submerged arc welding course

The submerged arc welder, as it turns out becomes a highly specialized machine operator, very few in Italy are able to use this machine, despite being a figure in high demand in the job market. Our Submerged Arc Welding Course, allows you to become a submerged arc welding specialist, able to precisely adjust, operate, master and control this particular welding machine. At the end of the welding course, you will take exam and upon successful completion, we will issue the Submerged Arc Welding License from the Italian Institute of Welding.

School of submerged arc welding

Our Submerged Arc Welding School is the only one in Italy to train highly skilled welders ready to work in companies, starting from 0.

Submerged arc welder

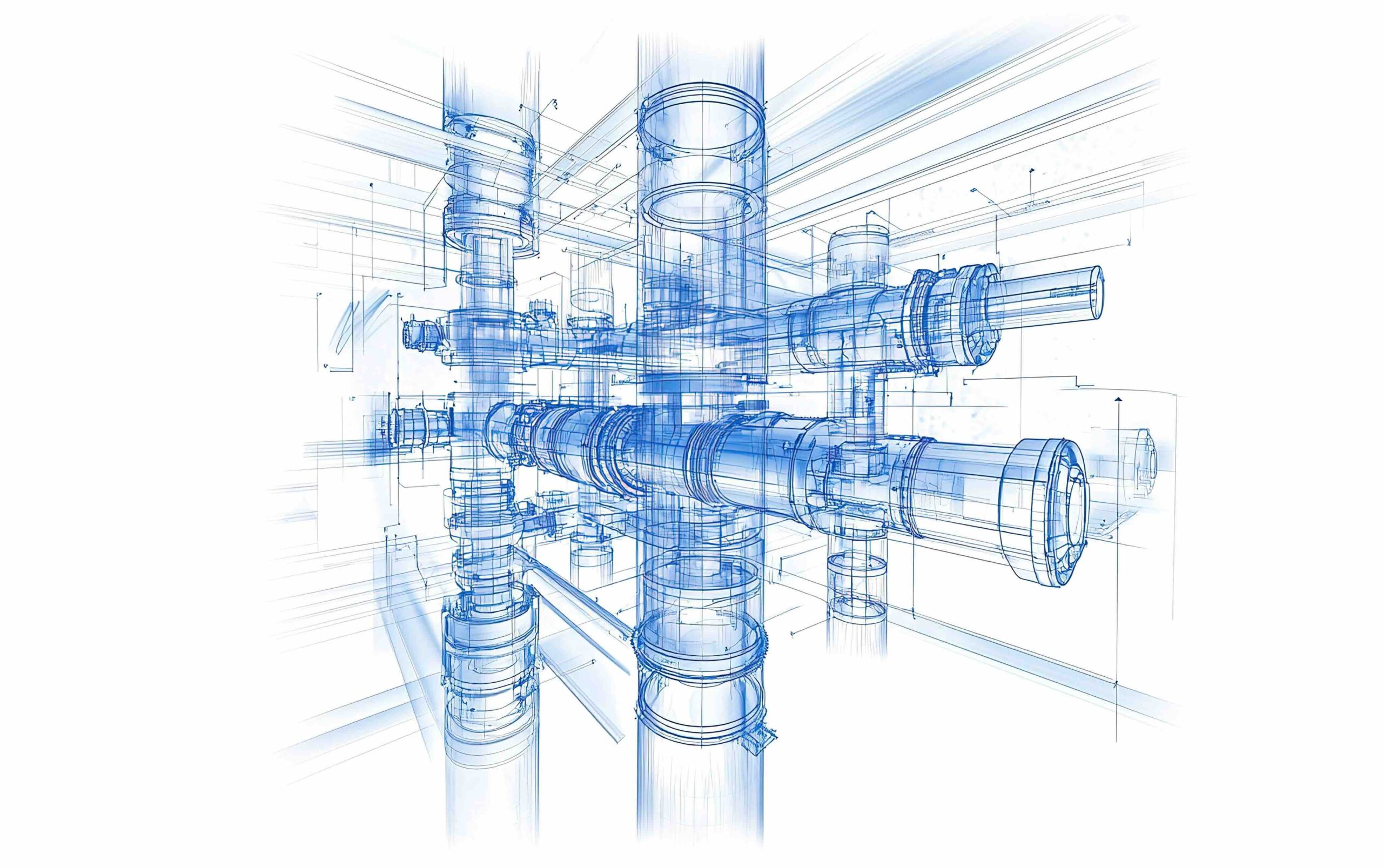

The submerged arc welding machine is composed as follows: a current generator of at least 1000 amperes is mounted at the base of a "manipulator," which is a metal arm with vertical and horizontal movement. The manipulator, is mounted on slewing ring usually manually. The vertical arm at the extreme tip mounts a small hopper containing the "welding flux," which thanks to a diffuser will cause the flux to settle on the joint-workpiece to be welded.

Behind the hopper takes place a wire dragging reel, where the wire spool (electrode) is placed, which will feed the weld continuously.

The submerged arc welder, complete with all the above-mentioned parts, is mounted on a wagon with iron wheels that moves on rails, this allows the movement of the machine, which in the case of horizontal welding will advance at the speed programmed by the submerged arc welder. The welding machine, thus equipped and well maneuvered by experienced submerged arc welder, deposits the filler metal inside the joint-workpiece to be welded, with extreme precision.

The submerged-arc welder works in symbiosis with an extremely necessary piece of machinery: The turners, a revolving machine, where the workpiece to be welded is placed, the turners will be programmed in symbiosis with the feed of the submerged-arc welder, so that the welding deposit into the joint is automatic and linear.

Unlike the other soldering procedures, we will not see any flash of solder because the weld pool will be totally submerged by the flux, which will have the dual function of antioxidant and at the same time releasing into the pool specific properties for the solder in question. The turners will rotate at the speed set by the submerged arc welder, while from the nozzle of the welder will come out the wire, which by short-circuiting inside the joint will begin the solder deposit.

For more information about our welding school's submerged arc welding course, please contact us.